Rainbow Ultima systems – Truck Washing Systems

Ultimate Cleaning Power for Regular and Irregular Fleets.

The new Rainbow Ultima Fleet Washer presents state-of-the-art technology to the large vehicle cleaning industry and fulfils extensive needs in a variety of applications. The top models combine advanced brushless and brush wash methods and clean all kinds of vehicles from cars to complex shaped tractors and trailers.

The Rainbow Ultima is equipped with prewash and high-pressure systems consisting of oscillating and profiling solid stream nozzle assemblies that have the best available cleaning power for tanker- and garbage trucks and other hard-to-clean shaped vehicles. For standard application Ultima can be equipped with conventional flat high-pressure nozzles.

KEY HIGHLIGHTS

- Top Class Cleaning Power for Hard-to-Clean Shaped Vehicles

- Ultimate Cleaning Power for Regular and Irregular Fleets.

- The Key Element – High-Pressure Washing

- Solid Stream Nozzles – for Far-Reaching Cleaning Power

- Triple Coverage Sweeping Technique for Enhanced Cleaning

Models available:

- Rainbow Ultima, base machine 3.6m max washing height

- Rainbow Ultima, base machine 3.9m max washing height

- Rainbow Ultima, base machine 4.2m max washing height

- Rainbow Ultima, base machine 4.5m max washing height

- Rainbow Ultima, base machine 4.8m max washing height

- Rainbow Ultima, base machine 5.1m max washing height

Unparalleled Cleaning Power

For Any Fleet

Automatic cleaning of street legal can be a challenge due to the variety of shapes and sizes of vehicles in the fleet.

A brush wash with or without a prewash is our standard methodology for cleaning vehicles with flat sides. However, cleaning vehicles with irregular shapes requires brush contouring and moveable spray bars placed at the optimal distance from the surfaces to be cleaned.

The Ultima control system is the most advanced in the industry. It offers a wide range of selectable and built-in programming elements, contouring modes, and functional features. The wash system can easily be customized to meet the needs of the fleet.

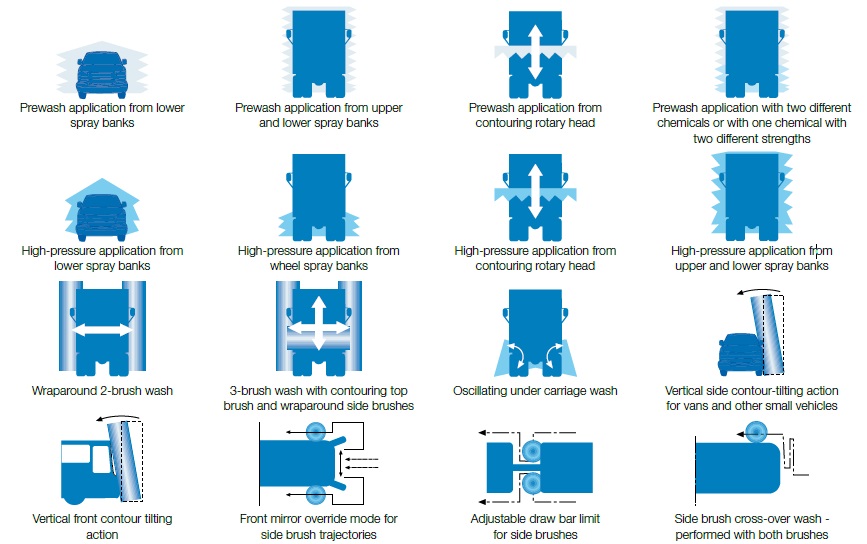

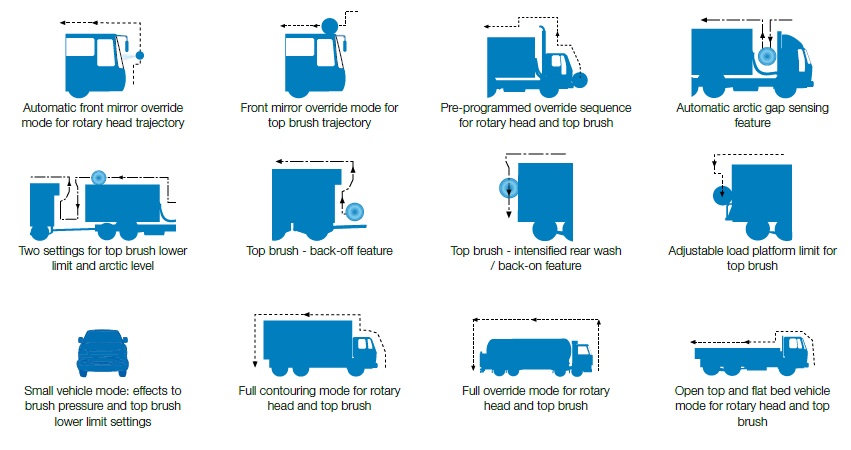

Program Elements, Contouring Modes And Functional Features

Heavy Duty Cleaning Power

For Irregular Shaped Vehicles

The Rainbow Ultima is designed to provide the best available cleaning power for tanker, garbage and other odd-shaped vehicles.

For standard applications, Ultima can be equipped with conventional flat, high pressure nozzles.

The Key Element Is High Pressure Washing

Transportation vehicles have a large number of areas that are beyond the reach of brushes. High pressure washing addresses this problem. The Rainbow Ultima is equipped with prewash and high pressure wash systems. Flat spray techniques are used for standard cleaning while, solid stream nozzles are designed for more demanding applications.

After a chemical prewash, high pressure jets use an oscillating and spinning motion to quickly and efficiently clean spaces on odd-shaped vehicles that brushes cannot reach. Additionally, these high pressure water jets remove sand and other coarse particles which could potentially scratch finishes during the brush stage of the wash.

Solid Stream Nozzles For Far Reaching Cleaning Power

While a flat spray pattern is ideal for short and medium distances, a solid stream spray pattern is more effective over greater distances.

The Ultima machines feature high pressure spray units with 3 parallel, solid stream nozzles. The water jets form a uniform area on the target surface.

Triple Coverage Sweeping

Technique For Enhancing Cleaning

Vertically sweeping jets clean the sides from sill to roof.

For enhanced cleaning, jets oscillate up and down so that they overlap each other. Similarly, the high-pressure water jets on the rotary head oscillate sideways.

The rotational motion of the head, together with the lateral oscillating pattern, directs the spray from the water jets into vehicle recesses that are beyond the reach of brushes, cleaning vertical and horizontal surfaces from bumper to bumper.

Wheel Wash

Wheel spray banks provide extra cleaning power for lower

vehicle areas.

Vertical Front Contour Tilting Brush Action

Brush inclination is an important feature in modern vehicle wash machines. The Rainbow Ultima’s solution is to pneumatically control the brush inclination instead of the traditional power push and tilt method. This unique solution gives an excellent wash result and is safe to use on the large windshield areas of many modern vehicles.

Chassis Washers

For Heavy Mud Removal

Ultima models can be equipped with either a static or high pressure oscillating chassis washer.

The chassis washer is installed at the entrance of the wash bay. The cleaning cycle starts when a vehicle drives over the spray head while entering the

wash bay.

A chassis washer can be fed either with a multistage centrifugal pump (18,5 kW, 340 l/min, 20 bar) or with piston pumps (2 x 18,5 kW,

2 x 114 l/min, 70 bar).

If the gantry is equipped with a high pressure system, no additional pump for the chassis wash is needed.

The power spray function of the wheel washer can be used together with general high pressure applications as well as with brush cycles.

Ultimate Cleaning Power

With Centri*Spinner® Arch

The Rainbow Spinner Ultima is equipped with Centri*Spinner® arch. It is designed to provide the best available cleaning power for tanker, garbage and other odd-shaped vehicles.

Centri*Spinner® Specifications

- Power Venturi Assisted Zero Degree Nozzles

- Hydrodynamic Rotational Speed Control

- Mechanical High Pressure Seal

- 1” NPT Connection

- 270-330 psi Operational Pressure Range

Trucks present a particular challenge for conventional brush wash systems, which is why InterClean’s touchless wash units are so popular. The InterClean Centri*Spinner® system will never damage the truck.

Dramatically reduced corrosion, improved accessibility to the maintenance areas of the vehicle, and improved general appearance are direct advantages of using a Centri*Spinner® Wash System.

Recycling Module

The heart of the InterClean system is the patented antiturbulent recycling and high pressure equipment module. The same module is used for all InterClean applications, from automated military tank washing to manual hand gun

applications.

Each module is capable of producing up to 300 GPM (1,250 l/min) recycled water continuously. The system is designed to recycle and aerate the wash water automatically, without changing filters or manual supervision.

The InterClean module facilitates the inexpensive and reliable use of high volumes of recycled wash water. The system is capable of operating under the most demanding vehicle wash conditions such as recycling the water used to wash garbage trucks. The system uses no chemicals or additives and is totally environmentally sound.

By using this effective yet inexpensive recycling system, InterClean Equipment is able to employ the full force of huge volumes of pressurized wash water, which create a cleaning impact that is simply not possible with other automatic vehicle washing systems.

To achieve recycled water volumes in excess of 300 GPM (1,250 l/min), multiple modules can be utilized in parallel.

The 1200 GPM (5,000 l/min), necessary in washing military tanks, is achieved by the use of four parallel InterClean modules.

The module is pre-wired, pre-plumbed and mounted on a skid. The overall dimensions of the unit are such that it can be shipped in standard road trailers, or in high cube 40 feet ocean freight containers.

The system has its own electrical panel, which includes a slave PLC that controls all system internal functions, such as liquid level monitoring and

adjustments. The system allows modem hook-up for remote control and trouble shooting.

Highlights And Special Features

- Overhead front and rear panels

- Hot dip galvanized frame structure

- AC inverter driven lift motors

- Wraparound side brushes

- Vertical front contour-tilting action

- Profiling top brush

- Stainless steel splash shields

- Stainless steel housing for control panel

- Bright LED positioning display

- Motor starters for brushes with soft start feature

- Touch sensitive safety flaps

- AC inverter driven gantry travel motors

- Centralized lubrication system

- Derailing locks

Prewash Arches

- Vertical full height pivoting spray banks

- Vertical full height pivoting and divided spray banks

- Vertical partial height pivoting spray banks for intensified treatment of vehicles lower areas

- Horizontal spray banks placed on contour profiling

rotary head

HP Arches

- Vertical full height pivoting spray banks – flat spray nozzles

- Vertical full height pivoting and divided spray banks – solid stream nozzles

- Wheel spray banks – solid stream nozzles to complete the full height oscillating solid stream system

- Horizontal spray banks placed on contour profiling rotary head – available with flat or solid stream HP nozzles.

Spinner Arches

- Power Venturi assisted zero degree nozzles

- Hydrodynamic rotational speed control

- Mechanical high pressure seal

- 1” NPT connection

- 270-330 psi operational pressure range

Why Choose Us?

Professional Service

High Quality Products

Extensive Knowledge

To find out more about our enhanced equipment, call us today.